Is your team running into the same roadblocks again and again? Do projects consistently miss deadlines, go over budget, or fail to meet quality standards? These aren't just minor frustrations; they are symptoms of inefficient processes that drain resources, stifle innovation, and demotivate even the most dedicated teams. In a competitive environment, how you work is just as important as what you produce. The key to breaking this cycle lies in systematically refining your workflows. This isn't about working harder; it's about working smarter by eliminating waste, reducing errors, and creating a culture of continuous enhancement.

This article is your practical toolkit for exactly that. We will explore nine powerful process improvement techniques that can revolutionize how your team operates, whether you're a startup, a student group, or a large distributed enterprise. We’ll skip the dense theory and dive straight into the practical application of methods like Lean, Six Sigma, and Kaizen. For each technique, you will find a clear explanation of what it is, who it's for, and actionable steps to implement it-with a special focus on making these strategies work for remote and hybrid teams.

The goal is to provide you with a clear roadmap to identify inefficiencies and a set of proven tools to fix them. You'll learn how to map your value stream, pinpoint the root cause of problems, and implement cycles of improvement that deliver measurable results. These concepts are foundational to building resilient and high-performing operations. To gain a deeper understanding of the foundational principles, you can refer to this comprehensive guide on process improvement techniques. Let's get started on transforming your team's productivity.

1. Lean Manufacturing

Lean Manufacturing is a powerful and systematic methodology focused on one primary goal: maximizing customer value by relentlessly eliminating waste. Pioneered by Toyota and its famed Toyota Production System, this approach redefines productivity by identifying and removing activities that consume resources but don't add value from the customer's perspective. It’s a philosophy built on continuous improvement, or kaizen, and deep respect for people.

The core of Lean revolves around identifying the "eight wastes" (often remembered by the acronym DOWNTIME): Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, and Extra-processing. By systematically targeting these inefficiencies, organizations can streamline their operations, reduce costs, and enhance quality.

Why Use Lean?

Lean is one of the most effective process improvement techniques when your primary goal is to increase efficiency and deliver more value with fewer resources. It's particularly useful for established processes that have become bloated over time. For example, Boeing famously used Lean principles to cut the assembly time for its 737 aircraft by 50%. Even non-manufacturing sectors benefit; Virginia Mason Medical Center applied Lean to healthcare, reducing patient wait times by an incredible 85%.

How to Implement Lean with Remote Teams

Applying Lean principles in a remote environment requires a focus on digital processes and communication.

- Start with Value Stream Mapping: Map your current digital workflows, from a customer request to final delivery. Use tools like Miro or Mural to visually collaborate and identify bottlenecks, delays (waiting), and unnecessary steps (extra-processing).

- Leverage Visual Management Tools: Use digital Kanban boards (like Trello, Asana, or Jira) to make work visible. This helps manage workflow, prevent overproduction of tasks, and highlight where team members are blocked.

- Engage Your Team: Foster a culture where every team member is empowered to identify waste. Create dedicated Slack or Teams channels for process improvement suggestions and hold regular virtual "Kaizen events" to brainstorm and implement small, incremental changes.

- Measure Everything: Track key performance indicators (KPIs) like cycle time, lead time, and defect rates. Use analytics from your project management tools to monitor progress and validate improvements.

2. Six Sigma

Six Sigma is a highly disciplined, data-driven methodology that uses statistical analysis to eliminate defects and reduce process variation. Developed by Motorola engineer Bill Smith in the 1980s, its ultimate goal is to achieve near-perfect quality, defined as no more than 3.4 defects per million opportunities. It's a rigorous approach to process improvement techniques that moves beyond guesswork, relying on hard data to pinpoint the root causes of problems and verify solutions.

The methodology is typically implemented through two key project frameworks: DMAIC (Define, Measure, Analyze, Improve, Control) for existing processes and DMADV (Define, Measure, Analyze, Design, Verify) for creating new processes. By following these structured phases, organizations can systematically enhance performance, improve customer satisfaction, and boost financial outcomes.

Why Use Six Sigma?

Six Sigma is the ideal technique when your primary objective is to dramatically reduce defects and solve complex problems where the root cause isn't obvious. It thrives in data-rich environments and is powerful for optimizing critical processes that have a direct impact on quality and customer satisfaction. For instance, under the leadership of Jack Welch, General Electric famously saved an estimated $12 billion over five years by embedding Six Sigma into its culture. Similarly, Motorola reduced its defect rate by 99.7%, saving $2.2 billion in the process.

How to Implement Six Sigma with Remote Teams

Applying the statistical rigor of Six Sigma in a remote setting depends on digital data collection and disciplined virtual collaboration.

- Define Clear Project Charters: Start with a well-defined project charter for a high-impact, manageable problem. Use shared documents (like Google Docs or Confluence) to clearly outline the problem statement, goals, scope, and team roles (Yellow Belt, Green Belt, Black Belt) so everyone is aligned from day one.

- Leverage Digital Data Collection: Use digital tools like surveys (Typeform, SurveyMonkey), analytics platforms (Google Analytics), and CRM data to gather the necessary metrics for the Measure and Analyze phases. This centralizes data, making it accessible to the entire distributed team.

- Use Statistical Software Collaboratively: Employ cloud-based or desktop statistical software (like Minitab or JMP) and use screen-sharing during virtual meetings to collaboratively analyze data. This ensures the entire team understands the statistical findings and can contribute to the analysis.

- Standardize Control Plans Digitally: Once improvements are implemented, use process management tools like Process Street or a shared knowledge base to document the new standard operating procedures (SOPs). This ensures the gains are sustained and the new process is followed consistently by all remote team members.

3. Kaizen

Kaizen, a cornerstone Japanese philosophy, translates to "change for the better" or "continuous improvement." It is a powerful long-term approach where small, incremental changes are consistently made over time to improve quality and efficiency. Unlike top-down, revolutionary changes, Kaizen involves every single employee, from the C-suite to the front-line workers, in the ongoing effort to identify and eliminate inefficiencies in their daily work.

The philosophy is built on the belief that a multitude of small, consistent improvements will compound into significant, large-scale benefits. It’s less about a single project and more about creating an organizational culture where everyone is empowered and encouraged to make things better every day. This collective ownership is what makes Kaizen one of the most sustainable process improvement techniques available.

Why Use Kaizen?

Kaizen is ideal for building a resilient, adaptable culture focused on long-term growth rather than just short-term fixes. It excels at improving morale and engagement because it empowers employees to influence their own work processes. For example, Toyota, a pioneer of Kaizen, receives millions of improvement ideas from its staff annually, with most being implemented. Similarly, Lockheed Martin used Kaizen events to reduce defects in its aircraft assembly by a remarkable 40%, demonstrating its impact on quality.

How to Implement Kaizen with Remote Teams

Implementing a culture of continuous improvement in a distributed setting hinges on deliberate communication and digital tools.

- Foster Psychological Safety: Create an environment where team members feel safe to suggest changes without fear of blame. Use regular, structured feedback sessions and one-on-ones to build trust and encourage open dialogue about what isn't working.

- Run "Kaizen Events" or Workshops: Dedicate specific times for the team to focus on a single process. Use digital whiteboards to brainstorm, map the current state, and collectively design improvements. These focused bursts of activity can generate significant momentum.

- Implement a Digital Suggestion System: Use a dedicated Slack channel, a form, or a specific board in your project management tool where anyone can submit an improvement idea. Crucially, have a clear process for reviewing, prioritizing, and providing feedback on every suggestion.

- Standardize and Celebrate Wins: When an improvement is successfully implemented, update documentation and standardize the new process across the team. Acknowledge the contributor and celebrate the small win in team meetings or company-wide communications to reinforce the culture. These events share similarities with agile ceremonies; learn more about conducting an effective retrospective meeting on remotesparks.com.

4. Business Process Reengineering (BPR)

Business Process Reengineering (BPR) is a radical and ambitious process improvement technique focused on fundamentally rethinking and redesigning core business processes from the ground up. Popularized by pioneers like Michael Hammer and James Champy, BPR isn't about making small, incremental changes; it’s about achieving dramatic, quantum-leap improvements in critical performance measures such as cost, quality, service, and speed.

Unlike continuous improvement methods that refine existing processes, BPR starts with a blank slate. It challenges deep-seated assumptions and asks, "If we were starting this company today, knowing what we know now and with current technology, how would we design this process?" The goal is to overhaul, not just tweak, workflows to align them directly with strategic objectives and customer needs.

Why Use BPR?

BPR is the go-to strategy when minor adjustments are no longer sufficient and a complete operational transformation is needed. It’s ideal for legacy processes that are broken, inefficient, and failing to meet modern demands. For instance, Ford famously used BPR to reengineer its accounts payable process, reducing headcount by 75% not by automating old steps but by completely changing how invoices were approved. Similarly, IBM Credit redesigned its loan approval process, slashing turnaround time from seven days to just four hours.

How to Implement BPR with Remote Teams

Implementing a BPR initiative in a remote setting demands exceptional leadership, communication, and digital collaboration.

- Start with the End in Mind: Begin by defining the desired outcome from a customer’s perspective. Use virtual workshops with tools like Miro or FigJam to map the ideal future-state process, completely ignoring the current one.

- Challenge Every Assumption: Create a cross-functional BPR team. Use asynchronous brainstorming tools and dedicated Slack channels to rigorously question every existing rule and procedure. Ask "why" repeatedly to uncover outdated assumptions.

- Leverage Technology as a Redesign Tool: Don't just automate old processes. Explore how modern tools (AI, cloud platforms, automation software) can enable entirely new ways of working. For example, can a centralized data hub eliminate the need for departmental handoffs?

- Communicate Radically and Transparently: BPR involves significant change, which can create anxiety. Leadership must use all-hands meetings, regular email updates, and open Q&A sessions to communicate the vision, the reasons for the change, and the expected benefits for both the company and employees.

5. Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive management philosophy where every single member of an organization participates in improving processes, products, and services to achieve long-term success through customer satisfaction. Unlike techniques that focus only on production, TQM embeds quality into the company's culture, from the executive suite to the front line. It’s a holistic approach that sees quality as a continuous journey, not a final destination.

Pioneered by quality gurus like W. Edwards Deming and Joseph Juran, TQM is built on the principle that the entire organization is responsible for quality. It emphasizes data-driven decision-making, employee empowerment, and a relentless focus on meeting and exceeding customer expectations. The goal is to prevent defects before they happen, rather than simply inspecting for them after the fact.

Why Use TQM?

TQM is one of the most powerful process improvement techniques when your goal is to build a sustainable, customer-centric culture that delivers consistent excellence. It’s ideal for organizations looking to improve customer loyalty and gain a competitive edge through superior quality. For instance, Xerox famously used TQM principles to regain significant market share from its competitors. Similarly, FedEx leveraged TQM to achieve an incredible 99.9% accuracy in package delivery.

How to Implement TQM with Remote Teams

Implementing TQM in a distributed setting hinges on creating a shared digital culture of quality and accountability.

- Establish a Clear Vision from Leadership: Leaders must champion the TQM philosophy through virtual town halls, clear documentation in shared wikis (like Confluence or Notion), and consistent messaging. This commitment sets the tone for the entire organization.

- Focus on the Digital Customer Experience: Use tools like user surveys (Typeform), feedback widgets (Hotjar), and analytics to deeply understand remote customer needs and pain points. Make this data accessible to all relevant teams.

- Implement Comprehensive Digital Training: Create a centralized learning hub with on-demand training modules covering quality principles, problem-solving tools, and the company's quality standards. This ensures every team member, regardless of location, is on the same page.

- Foster a Culture of Continuous Feedback: Use dedicated channels in Slack or Teams for quality improvement suggestions. Encourage peer reviews and transparent, constructive feedback on project management platforms to continuously refine work and processes. A key component involves implementing robust modern quality assurance processes to ensure consistent output and customer satisfaction.

6. Value Stream Mapping

Value Stream Mapping (VSM) is a lean management technique used to analyze, visualize, and improve all the steps involved in a product or service delivery process. It goes beyond a simple flowchart by illustrating both the flow of materials and the flow of information required to bring value to the customer. Popularized by practitioners like Mike Rother and John Shook within the Toyota Production System, VSM provides a holistic view of the entire system, from raw material to final delivery.

The primary goal of this process improvement technique is to identify and eliminate waste, specifically non-value-adding activities. By creating a visual "map" of the current state, teams can clearly see bottlenecks, delays, and areas of inefficiency. This clarity allows them to design a more streamlined "future state" with a focus on optimizing flow and reducing lead time.

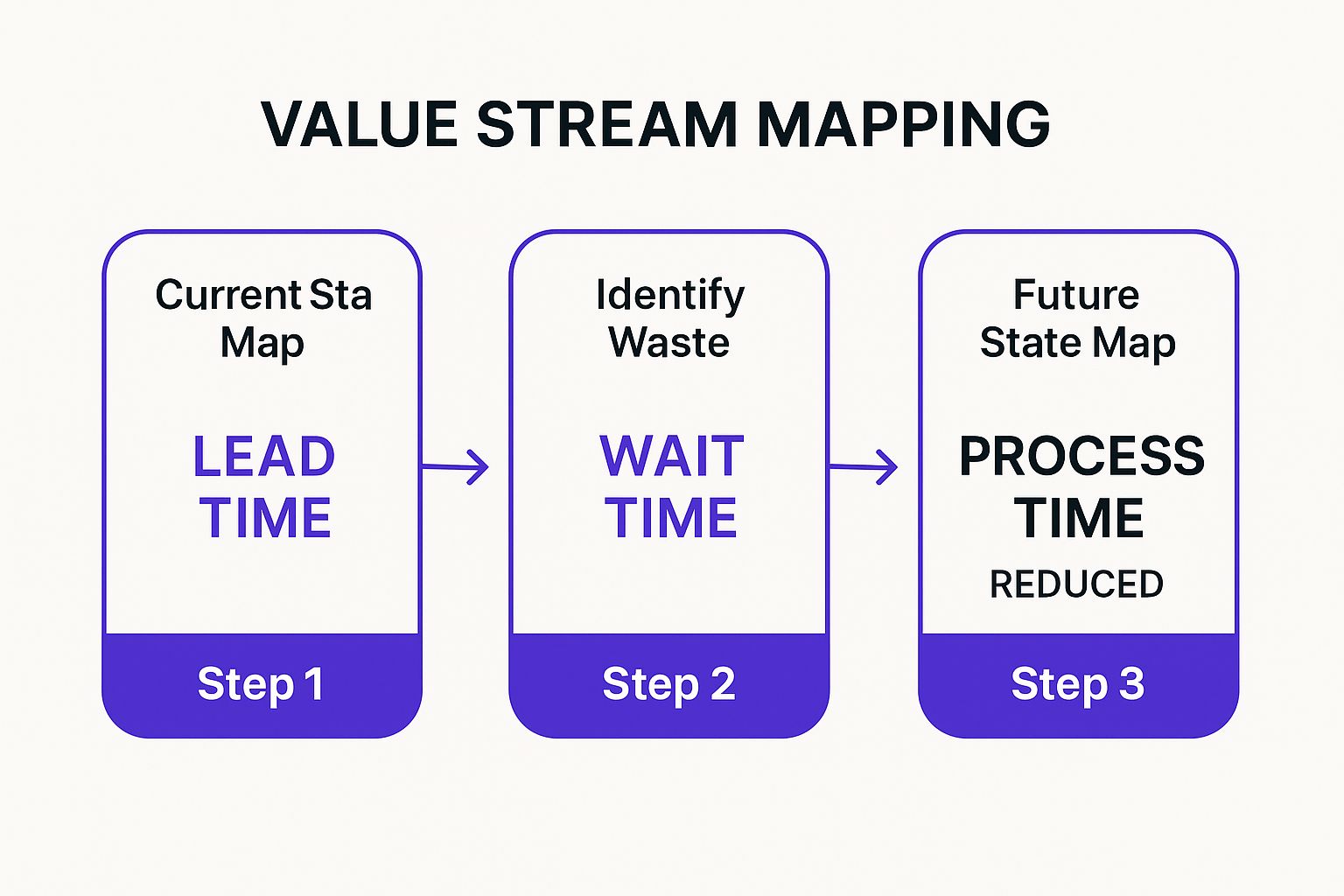

The infographic below illustrates the core journey of a Value Stream Mapping initiative, from understanding the current process to designing an improved future state.

As the diagram shows, the key is to pinpoint and reduce "Wait Time," which often constitutes the largest portion of the total "Lead Time," thereby making the value-added "Process Time" more efficient.

Why Use Value Stream Mapping?

VSM is one of the best process improvement techniques for gaining a comprehensive, system-level understanding of your operations. It’s ideal when you need to see the "big picture" and understand how different steps interact and impact overall delivery time. For example, Intel used VSM to reduce a key manufacturing cycle time by 40%, while Lantech, a packaging equipment manufacturer, dramatically cut its lead time from 16 weeks to just five days by redesigning its value stream.

How to Implement Value Stream Mapping with Remote Teams

Executing VSM in a remote setting relies on digital collaboration and a shared understanding of the workflow.

- Select a Product Family: Start with a single, high-impact product or service. Focus your efforts where improvement will deliver the most value.

- Create a Digital Current State Map: Use a collaborative whiteboard tool like Miro or FigJam. Schedule a series of virtual workshops to "walk the process" with team members from different departments. Map every step, including handoffs, delays, and information flows.

- Identify and Quantify Waste: Analyze the digital map to find bottlenecks, long wait times, and redundant tasks. Use data from your project management and CRM tools to quantify the impact of this waste, such as time spent waiting for approvals or information.

- Design the Future State: Once waste is identified, use idea generation techniques in a brainstorming session to design an ideal future state map. This new map should represent a leaner, faster process that eliminates the identified waste and improves flow. Create an action plan to implement the changes needed to achieve it.

7. PDCA Cycle (Plan-Do-Check-Act)

The PDCA Cycle, also known as the Deming Cycle, is a powerful and iterative four-step management method used for the continuous improvement of processes and products. It provides a simple yet effective framework for solving problems and implementing changes in a structured way. This scientific approach ensures that improvements are based on data and that organizations learn from every attempt.

The cycle consists of four distinct phases: Plan (identify a goal or problem and hypothesize a solution), Do (implement the plan, preferably on a small scale), Check (measure and analyze the results against expectations), and Act (if successful, standardize the solution; if not, begin the cycle again with new knowledge). This continuous loop drives incremental progress and embeds a culture of improvement.

Why Use the PDCA Cycle?

The PDCA Cycle is one of the most versatile process improvement techniques because it can be applied to almost any situation, from complex product development to simple workflow adjustments. It’s ideal for situations requiring a controlled, data-driven approach to change. For example, software companies often use PDCA principles within their agile development sprints to test new features. In healthcare, hospitals use the cycle to systematically reduce patient safety incidents by testing new protocols, checking their impact, and rolling out successful changes.

How to Implement the PDCA Cycle with Remote Teams

Applying PDCA in a remote setting thrives on clear communication and digital tools that support each phase of the cycle.

- Plan with Collaborative Tools: Use virtual whiteboards like Miro or brainstorming sessions on Zoom to collectively define the problem and map out the plan. Document the hypothesis, expected outcomes, and metrics for success in a shared space like a Confluence page or Google Doc. This phase sets the foundation for a strong decision making process.

- Execute Small-Scale Pilots (Do): In the "Do" phase, implement the change with a small group or a single project. This limits risk. For a remote team, this could mean testing a new communication protocol on one project team or trying a new software tool with a few volunteers before a company-wide rollout.

- Check with Shared Dashboards: Systematically collect data on the pilot's performance. Use shared analytics dashboards (from tools like Jira, Hubspot, or custom-built dashboards) to track KPIs in real-time. Hold a specific virtual meeting to review the data and compare it to the initial plan.

- Act and Document: Based on the results, decide whether to adopt, adapt, or abandon the change. If the change was successful, update official process documentation and communicate the new standard practice to the entire team via Slack channels and a formal announcement. Document lessons learned regardless of the outcome.

8. Root Cause Analysis (RCA)

Root Cause Analysis (RCA) is a disciplined, systematic process for identifying the true origin of a problem. Instead of merely addressing the immediate symptoms, RCA digs deeper to uncover the fundamental cause, ensuring that a problem is permanently solved and cannot recur. It’s a foundational problem-solving method that shifts focus from blaming individuals to improving the underlying processes and systems.

The core principle of RCA is that problems are best solved by correcting their root causes, rather than just treating the surface-level effects. Popular techniques used within RCA include the 5 Whys, developed by Sakichi Toyoda, and the Fishbone (or Ishikawa) Diagram. By repeatedly asking "Why?" or mapping out potential causes, teams can move past obvious symptoms and pinpoint the primary failure point that triggered the entire issue.

Why Use Root Cause Analysis?

RCA is one of the most critical process improvement techniques when you are dealing with recurring problems, major failures, or safety-critical incidents. It stops the cycle of "firefighting" where the same issues reappear. For instance, NASA famously uses RCA to investigate spacecraft failures to prevent catastrophic events. Similarly, IT departments leverage it to diagnose the source of system outages, preventing future downtime that could cost a business millions.

How to Implement Root Cause Analysis with Remote Teams

Conducting RCA remotely requires structured collaboration and a commitment to data-driven investigation.

- Clearly Define the Problem: Start with a precise and agreed-upon problem statement. Use a shared document or virtual whiteboard to outline exactly what happened, when it happened, and its impact. This ensures everyone is solving the same problem.

- Gather a Diverse Virtual Team: Assemble a cross-functional team on a video call. Include people with different perspectives on the process: engineers, customer support, and project managers. This diversity is key to uncovering all potential causes.

- Use Collaborative Analysis Tools: Facilitate a "5 Whys" or Fishbone Diagram exercise using a digital whiteboard like Miro or Mural. These tools allow team members to contribute ideas simultaneously and visually map the connections between symptoms and their underlying causes. This is a core part of many creative problem-solving techniques.

- Focus on System Failures, Not Blame: Create a psychologically safe environment where team members can speak openly without fear of being blamed. The goal is to identify weaknesses in the process, not to single out individuals.

- Implement and Monitor Solutions: Once the root cause is identified, assign clear action items in your project management tool. Track the implementation of these corrective actions and monitor KPIs to ensure the problem does not reoccur.

9. 5S Methodology

The 5S Methodology is a powerful workplace organization system designed to create a clean, orderly, and efficient environment. Originating from Japan as a fundamental component of Lean Manufacturing, its name refers to five Japanese words: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). This systematic approach eliminates waste by organizing the workspace for optimal effectiveness and safety.

At its core, 5S is about creating a space where everything has a place, and everything is in its place. This not only reduces wasted time searching for tools or information but also makes abnormalities, like missing items or potential safety hazards, immediately obvious. It is a foundational practice that enables more advanced process improvement techniques to succeed.

Why Use 5S?

The 5S Methodology is an excellent starting point for any process improvement journey because it addresses the physical and digital environment where work happens. It's ideal when you need to reduce clutter, improve safety, and establish a baseline for discipline and efficiency. For example, Harley-Davidson used 5S to improve production efficiency by 30% by organizing its assembly lines. Similarly, manufacturing giant Caterpillar reduced inventory and improved workflow by systematically organizing its facilities.

How to Implement 5S with Remote Teams

Implementing 5S in a remote setting requires adapting its principles from the physical shop floor to the digital workspace.

- Sort (Seiri): Dedicate time for teams to clean out their digital environments. This includes archiving old files, deleting unused applications, organizing email inboxes, and decluttering browser bookmarks. The goal is to remove anything that is not essential for current work.

- Set in Order (Seiton): Create a standardized digital filing system. Use a clear and consistent folder structure on shared drives like Google Drive or SharePoint. Define naming conventions for documents, projects, and communication channels (e.g., [ProjectName]-[DocumentType]-[Date]).

- Shine (Seiso): Schedule regular "digital cleaning" days. This could be a monthly event where team members perform maintenance tasks like clearing caches, updating software, and running security scans. This also applies to tidying up project management boards by archiving completed tasks and closing old tickets.

- Standardize (Seiketsu) & Sustain (Shitsuke): Document your new digital organization standards in a central wiki or handbook. Conduct periodic audits of shared drives and communication channels to ensure compliance. Recognize and celebrate teams that consistently maintain their organized digital spaces to build a lasting culture of order.

Process Improvement Techniques Comparison

| Methodology | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Lean Manufacturing | Moderate to High 🔄 (6 months to 2 years, cultural change) | Moderate to High ⚡ (training, leadership commitment) | Waste reduction, improved quality, faster delivery 📊 | Manufacturing and operations seeking waste elimination | Sustainable competitive advantage, employee empowerment ⭐ |

| Six Sigma | High 🔄 (statistical training and certification) | High ⚡ (data tools, training, leadership support) | Near-perfect quality, defect reduction 📊 | Processes needing defect elimination and statistical control | Data-driven decisions, significant cost savings ⭐ |

| Kaizen | Low to Moderate 🔄 (incremental, bottom-up) | Low to Moderate ⚡ (employee involvement) | Continuous small improvements, morale boost 📊 | Organizations fostering continuous improvement culture | Quick implementation, low risk improvements ⭐ |

| Business Process Reengineering (BPR) | Very High 🔄 (radical redesign, long timeline) | Very High ⚡ (technology, resources, change management) | Dramatic performance improvements 📊 | Organizations needing breakthrough process transformation | Potential for breakthrough gains, tech leverage ⭐ |

| Total Quality Management (TQM) | High 🔄 (long-term cultural transformation) | High ⚡ (training, system-wide involvement) | Improved customer satisfaction and quality 📊 | Organizations aiming for comprehensive quality and culture | Comprehensive approach, competitive advantage ⭐ |

| Value Stream Mapping | Moderate 🔄 (time-consuming mapping and updates) | Moderate ⚡ (training, software tools) | Waste identification, process flow clarity 📊 | Lean initiatives identifying process bottlenecks | Visual process clarity, cross-functional insights ⭐ |

| PDCA Cycle (Plan-Do-Check-Act) | Low 🔄 (simple iterative cycle) | Low ⚡ (minimal resources) | Systematic small improvements, risk reduction 📊 | Any process needing continuous improvement | Easy to understand and apply, promotes learning ⭐ |

| Root Cause Analysis (RCA) | Moderate to High 🔄 (investigative, analytical) | Moderate to High ⚡ (expertise, data collection) | Problem recurrence prevention, systemic fixes 📊 | Problem-solving in quality, safety, and reliability | Addresses root causes, builds organizational learning ⭐ |

| 5S Methodology | Low to Moderate 🔄 (discipline and maintenance) | Low to Moderate ⚡ (employee involvement, audits) | Organized, safe, efficient workplaces 📊 | Workplace organization and foundational lean initiatives | Improves safety and efficiency, foundation for lean ⭐ |

Start Your Improvement Journey Today

You have now explored a powerful arsenal of nine distinct process improvement techniques, each offering a unique lens through which to view and refine your organization's operations. We've journeyed from the waste-elimination principles of Lean Manufacturing to the rigorous, data-driven methodology of Six Sigma. We've seen how Kaizen champions small, continuous changes and how Business Process Reengineering (BPR) dares to ask for radical reinvention.

The key takeaway is that there is no single "best" method. The true power lies in understanding the core philosophy behind each and selecting the right tool for the specific challenge you face. Think of it as a craftsman's toolbox: you wouldn't use a sledgehammer to drive a small nail, nor would you use a tiny screwdriver to break down a wall. The same principle applies here.

From Knowledge to Action: Your First Steps

The sheer volume of information can feel overwhelming, but the path to meaningful improvement begins with a single, focused step. Resist the urge to launch a massive, company-wide initiative implementing all nine techniques at once. This approach often leads to confusion, burnout, and ultimately, failure.

Instead, start small and build momentum. Here’s a practical roadmap to get you started:

- Identify a Single Point of Friction: What is one recurring problem that consistently frustrates your team? It could be a slow approval process, a frequently missed deadline, or a task that generates excessive errors. Choose a problem that is both visible and manageable.

- Select a Simple Starting Tool: For your first initiative, pick a straightforward technique. The PDCA Cycle (Plan-Do-Check-Act) is an excellent starting point for structured problem-solving. Alternatively, use a Root Cause Analysis (RCA) technique like the "5 Whys" to dig beneath the surface of the issue.

- Involve Your Team (Especially Remotely): Process improvement is a team sport, not a solo endeavor. This is especially critical for remote and hybrid teams where clear, documented processes form the backbone of effective collaboration. Bring your team into the conversation early. They are the ones living the process every day and often hold the most valuable insights.

- Measure and Communicate: Define what success looks like before you start. How will you know if the change was an improvement? Track a simple metric. Once you've completed a cycle, share the results-both successes and lessons learned-with everyone involved. Transparency builds trust and encourages future participation.

The True Value of Continuous Improvement

Mastering these process improvement techniques is about more than just boosting efficiency or cutting costs. It's about building a culture of excellence, resilience, and innovation. When your team is empowered to identify and solve problems, they become more engaged and invested in the organization's success.

Key Insight: A culture of continuous improvement transforms your organization from a static entity that reacts to change into a dynamic one that drives it. It creates a system where every employee, from the front-line intern to the senior executive, is a partner in progress.

In a rapidly evolving business landscape, especially one with distributed teams, your processes are your competitive advantage. Smooth, efficient, and well-understood workflows reduce friction, enable faster decision-making, and create the operational stability needed to pursue ambitious goals. By committing to this journey, you are not just fixing today's problems; you are building a stronger, more adaptable organization ready to thrive in any future. The journey of a thousand miles begins with a single step, and your first step starts now.

Ready to put these principles into action but need a central hub to manage your ideas and track progress? Bulby provides the collaborative platform your team needs to capture insights, organize improvement projects, and turn great ideas into tangible results. Start your free trial of Bulby today and build your culture of continuous improvement.